From Ukraine peace plans to Kazakh uranium—all that and more in our new nuclear digest

Our November Nuclear Digest by Bellona’s Environmental Transparency Center is out now. Here’s a quick taste of just three nuclear issues arising in U...

News

Publish date: April 14, 2015

News

The significant contribution of the iron and steel sectors towards CO2 emissions is due to the energy intensity of steel production, its reliance on carbon-based raw materials and fuels, and the large volumes of steel produced. Total UK steel sector emissions amounted to 16.6 million tonnes of CO2 in 2011, and inflating to 22.8 million tonnes in 2013. The sector accounts for 9% of industry’s energy use, the majority of which is used for high-temperature processes.

Despite industry’s long-term commitment to reduce its CO2 emissions, the UK iron and steel sector continued to consume large amounts of energy, over 70% of which is used to provide heat, often at very high temperatures (over 1,000°C). The steady increase of emissions in recent years also reflects the limits to technological opportunities that can further improve energy efficiency, with only relatively small incremental improvements in energy consumption.

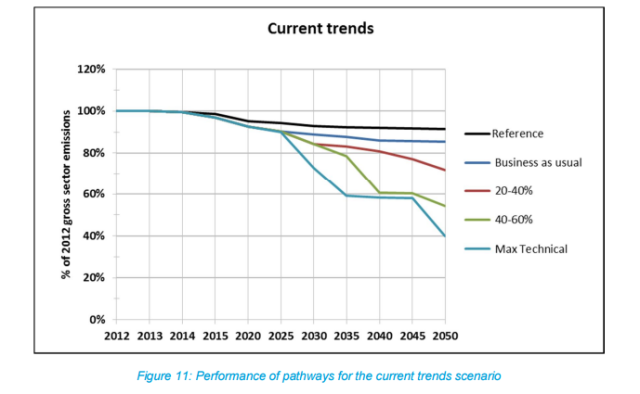

The study concludes that CCS technology will need to play a key role in the deep decarbonisation of the iron and steel sector. Its significant contribution is made clear in the graph below, based on the following assumptions (DECC, March 2015):

The study also notes that the ‘Max Tech’ emission reduction pathway is based on the assumption of availability of CCS technologies. In the absence of CCS, only emission reductions of 41% can be achieved, as opposed to 60% or more with CCS. What is more, the combination of CCS with sustainable biomass would achieve a 63% emissions reduction.

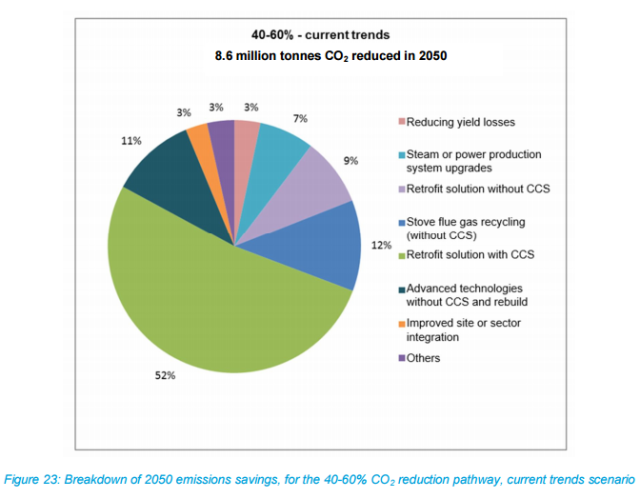

The graph below illustrates a breakdown of the 2050 emissions savings for the 40-60% CO2 reduction pathway. In this scenario, the key role of CCS is made clear, as 52% of emissions reduced in 2050 would stem from the application of CCS.

The DECC studies make the case for CCS in energy intensive industries increasingly clear. In a society and economy with an urgent need to reduce emissions, the pathway to retaining and growing the industrial and employment base is through CCS. For more on the case of decarbonising the cement sector, read this article.

Our November Nuclear Digest by Bellona’s Environmental Transparency Center is out now. Here’s a quick taste of just three nuclear issues arising in U...

For three years now, Bellona has continued its work in exile from Vilnius, sustaining and expanding its analysis despite war, repression, and the collapse of international cooperation with Russia in the environmental and nuclear fields

The Board of the Bellona Foundation has appointed former Minister of Climate and the Environment Sveinung Rotevatn as Managing Director of Bellona No...

Økokrim, Norway’s authority for investigating and prosecuting economic and environmental crime, has imposed a record fine on Equinor following a comp...