Working to discern patterns of environmental disinformation in an online world

For the past eight years, disinformation has dominated news around elections all over the world. Despite this, it is still a widely misunderstood con...

News

Publish date: March 31, 2015

News

A separate report for each industry sector has been made available, laying out the potential pathways for decarbonisation. The emphasis is on collaborative working between industry, government and other stakeholders, while taking into consideration issues such as supply chains, customer demand, the wider global perspective, and technical and commercial barriers.

CCS is pre-requisite for decarbonising cement

The roadmap for CO2 reductions from the UK cement industry puts CCS at the centre of any deep decarbonisation of the industry. The research focuses on CO2 reduction from UK-based facilities, but the findings are representative of the emissions reduction potential of the European and global cement industry.

Current CO2 emissions from the UK cement sector amount to 7.5 million tonnes per year. 60% to 65% of this CO2 arises not from the combustion of fossil fuel, but from the conversion of limestone to calcium clinker, the major constituent of cement. The roadmap examines a diverse range of technologies that can be used to reduce these emissions over time to 2050 and finds CCS is essential.

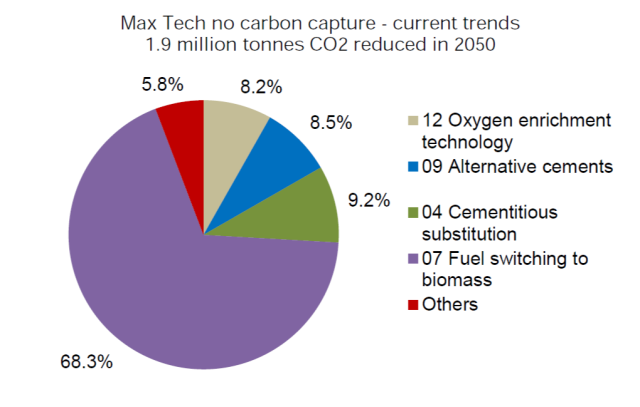

Contrasting the two scenarios that attempt to achieve substantial CO2 reductions makes evident how critical CCS will be in the supply of low carbon building materials. The first scenario “max tech no carbon capture” employs all anticipated technologies to reduce the CO2 intensity of cement production. However, even with a diverse range of technologies and efficiency improvements CO2, emissions from the sector are only reduced by 25% in 2050 (1.9 million tonnes of CO2 avoided).

The diverse technologies needed to achieve the underwhelming CO2 reduction of the scenario with no CCS include:

It is clear that the combined CO2 reductions of these technologies will not be sufficient in reducing CO2 emissions from the UK cement industry. At present the global cement industry is responsible for 5% of global emissions. In the absence of CCS the combined use of the best available technologies to all plants can only reduce those emissions by 25%. Indeed even this 25% reduction may not be feasible due to high competition (eg. aviation fuel) and challenges in ensuring sustainability for biomass.

CCS scenario achieves greater CO2 cuts

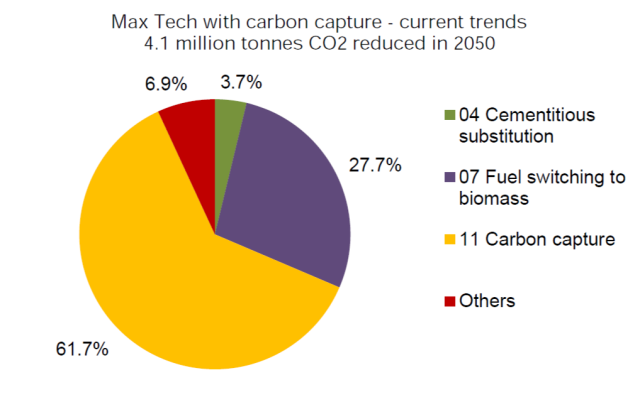

The scenario “max tech with carbon capture” includes a diverse range of CO2 reduction technologies and CCS. These together achieve CO2 reductions of 54% in 2050 (4.1 million tonnes of CO2 avoided). The application of CCS alone achieves 2.5 million tonnes of CO2 reduction in 2050. In contrast the full decarbonisation of the electricity grid contributes emissions reductions in 2050 of 8.5%.

The technologies, including CCS, needed to achieve the highest CO2 reduction include:

The study concludes that “CCS presents the highest emissions reduction contribution by 2050 in the Max Tech with CCS pathway under current trends scenario, and therefore represents the primary potential option to reduce CO2 emissions in the cement sector.”

Next step: CO2 transport and storage infrastructure

The roadmap rightly identifies the crucial need for CO2 transport and storage infrastructure to enable the required CO2 reductions from the cement industry. Such CO2 transport and storage networks will need to be present throughout Europe in order to decarbonise not only cement but also other CO2-intensive industries such as steel and refining, as well as the power sector.

Bellona agrees that collaboration both within the sector and externally is necessary to establish these transport and storage networks, along with the availability of sources of funding appropriate to this type of shared infrastructure.

As with the ZEP Business models for commercial CO2 transport and storage, the DECC study also recommends that a future strategy for the development of a CO2 transportation network should be considered with government taking a lead. The report recommends a UK CO2 Pipeline Roadmap to provide clarity for future CCS infrastructure.

For the past eight years, disinformation has dominated news around elections all over the world. Despite this, it is still a widely misunderstood con...

A ruling by the European Free Trade Association Court that Norway’s continental shelf falls under the European Economic Area Agreement could dramatic...

Bellona held a seminar on countering Russian disinformation in the Arctic at the Arctic Frontiers international conference in Norway

Our December Nuclear Digest, reported by Bellona’s Environmental Transparency Center, is out now. Here’s a quick taste of three nuclear issues arisin...